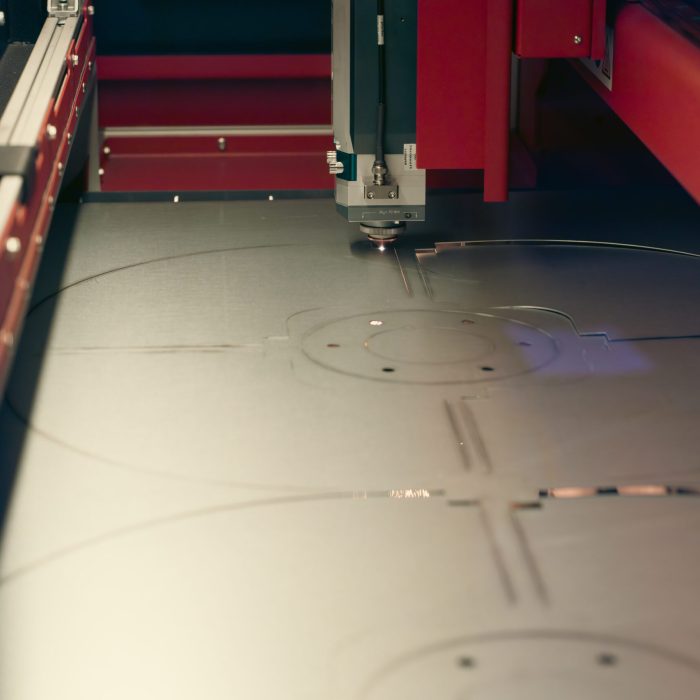

Laser Cutting

Laser cutting is the most recent cutting technique in our range, and demand for it in the market continues to rise. For thin sheet material, a laser cutting machine is extremely fast and efficient. Additionally, there are many automation options available.

How does laser cutting work?

Have you ever smoldered paper or grass with a magnifying glass? Laser cutting is similar, but on a larger scale.

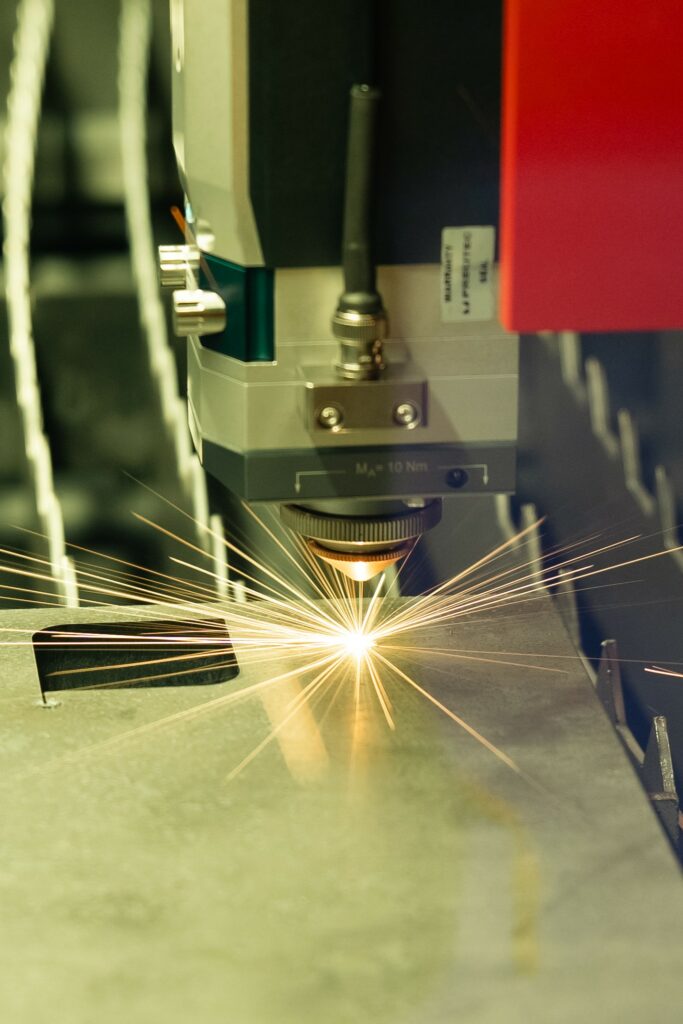

In a laser beam, the focus is set so that the diameter of the light circle is only fractions of a millimeter. This makes the intensity of the beam so great that the material melts or even evaporates. This allows a laser cutting machine to make very precise and narrow cuts.

What should you consider with laser cutting machines?

- Fast and accurate

Laser cutting machines can cut at very high speeds without sacrificing accuracy. This significantly increases the production speed and makes post-processing unnecessary in most cases. - Quiet

With laser cutting, the cutting edges are extremely narrow and precise. This not only allows complex contours to be cut, but also limits material loss. - Automation

MicroStep’s laser cutting machines offer many possibilities in terms of automation. For example, the machine can be equipped with a system for automatic loading and unloading of plates, which greatly increases productivity. - Return on investment

With a laser cutting machine, you can cut a wide range of metals. The technique is used in various production applications because of its precision, speed and versatility.

Vragen over MicroStep-lasersnijmachines? Bekijk hier de meest gestelde vragen.

Our references in laser cutting

Dulasta | MicroStep

Read more →

Lumetal | MicroStep

Read more →

MicroStep

MicroStep is a high-end brand that offers a wide range of possibilities. From smaller installations to complete production lines with the latest technologies. With more than 250 completed projects, we will find the perfect machine for you as well.

Esprit

Esprit is een Europese fabrikant van compacte en budgetvriendelijke lasersnijmachines die uitzonderlijke snijprestaties leveren. Ze zijn snel geïnstalleerd, waarna jij er meteen mee aan de slag kan.