About Hulens Technology

Hulens Technology develops all kinds of props for TV productions. Did you watch ‘Code van Coppens’? Or did you visit JOE’s beach house? Then you most probably saw their work. In short: they are the place to go for production companies that need specific customisation.

Some time ago, Hulens received a request. They were asked to make props for a TV show during a period of several months. The problem? Everything had to be made out of metal.

Until then, metal cutting was something they did with a grinding wheel. Or they worked with a firm that did have a plasma cutter.

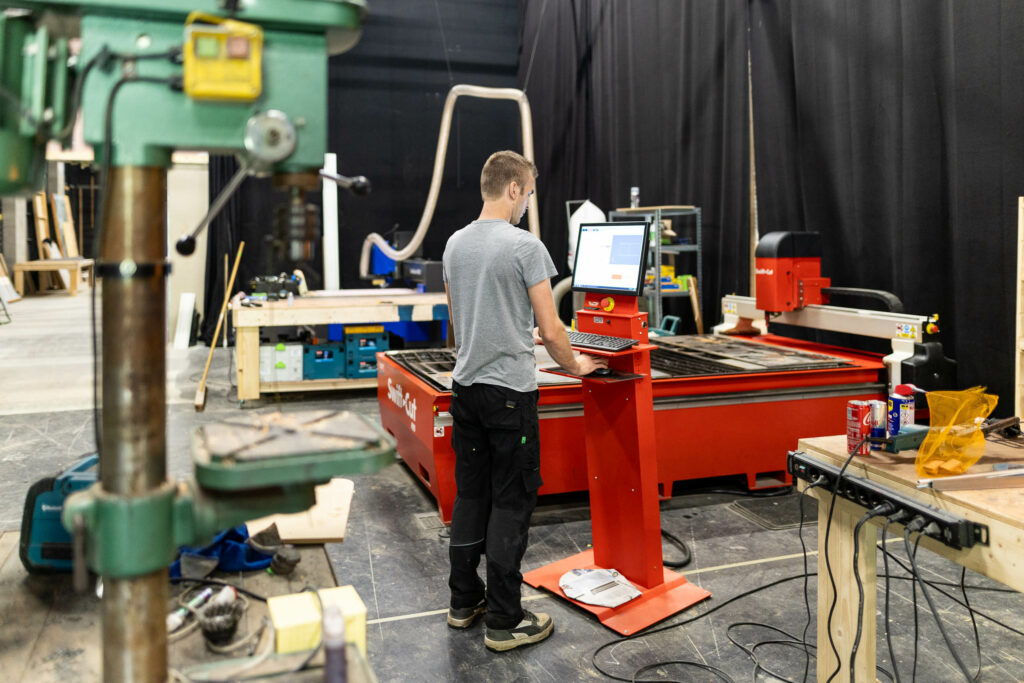

The solution? A Swift-Cut Pro. Managing director Dries knew very quickly what they needed. “I watch a lot of videos of Adam Savage from Mythbusters and of Colin Furze. They use the same machine, and those cuts just looked good. That’s how I ended up with WCW.”

In barely one month, Dries had done his research and his Swift-Cut Pro was ready. 2 days of training later, the team could get to work.

“We already have a wood cutting machine. So we were already familiar with this type of machine. But that training ensured that we could start smoothly. Before buying a machine, there is always the doubt whether you will use it enough. After all, it is a big investment. But I can say that the results are completely within expectations. We use the Swift-Cut intensively.

Maybe even too intensively.

“One day we were going to have lunch. But no one had provided forks. We used our Swift-Cut to make our own forks. And that worked well.”

Such a cutting machine contains many moving parts. And people who work with machines will know this can cause some problems.

“One day, the Swift-Cut stopped cutting. But that was solved immediately. I called WCW, and via Teamviewer they were able to make an analysis of the machine. Turned out there were dirt particles blocking a specific part. A few minutes later, we were back up and running as if nothing had happened.”

Meanwhile, Hulens has been using the Swift-Cut for a while.

“I think the Swift-Cut is running almost every day now. I can really recommend it to any metalworker. If I need other machines in the future, WCW is definitely a firm I will take into consideration.

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

Looking for a cutting or laser machine?

Demo in showroom or no-obligation appointment?

Or call us on +32 3 475 98 25