About Efesto

- look for a way to get more work done;

- work overtime.

“I had seen the Swift-Cut at work at a trade fair about three years ago. After that, I started looking for more information about it. I got in touch with WCW. There I had the feeling I was talking to a specialist rather than a salesman, which was really nice.

I often trust my intuition, so my decision to purchase a Swift-Cut was made fairly quickly.”

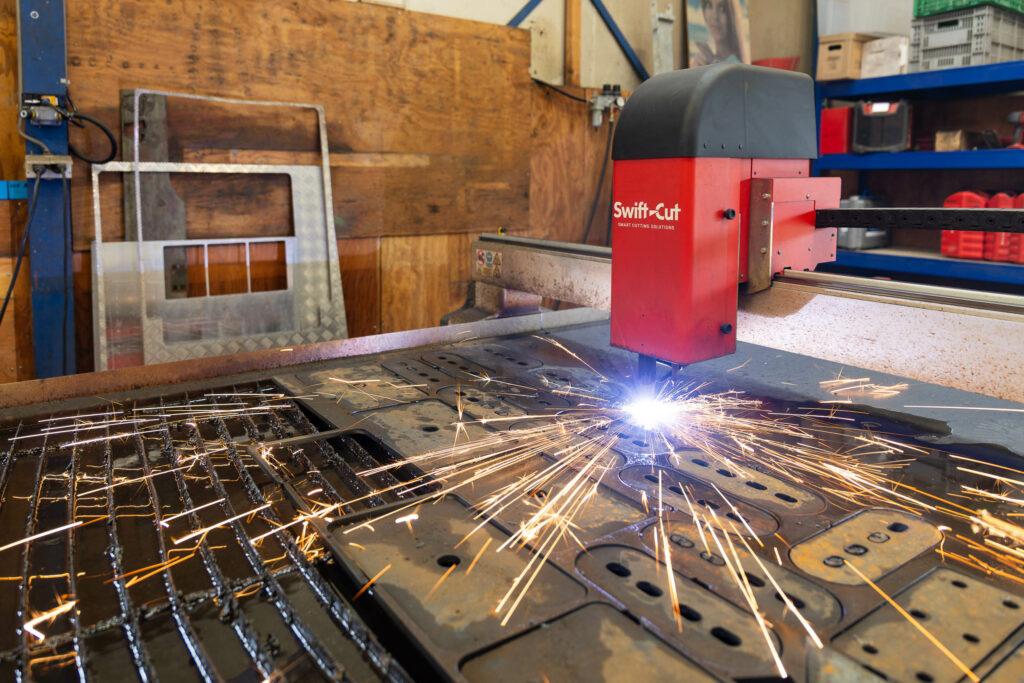

Not much later, the Swift-Cut was in Efesto’s workshop. How do they use the machine?

“Today I mainly use the Swift-Cut for the slightly rougher work. Do I have a customer for whom a luxurious finish is important? Then I’m more likely to outsource that project to someone with a laser cutting machine (WCW also sells laser cutting machines, ed.).

The Swift-Cut is perfect for a small company of up to 10 people, like ours. “Especially if you use the machine regularly.”

And can everyone use the machine smoothly?

“Yes, surely. There was an initial training session soon after the installation. But what really adds value is that WCW provides a second training session after a few months. After such an initial training, you don’t remember everything. Such additional training ensures that we use the machine correctly. Until today, I haven’t had any real problems with or questions about the machine either.”

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

Looking for a cutting or laser machine?

Demo in showroom or no-obligation appointment?

Or call us on +32 3 475 98 25