CASE

Metalix | Royal IHC

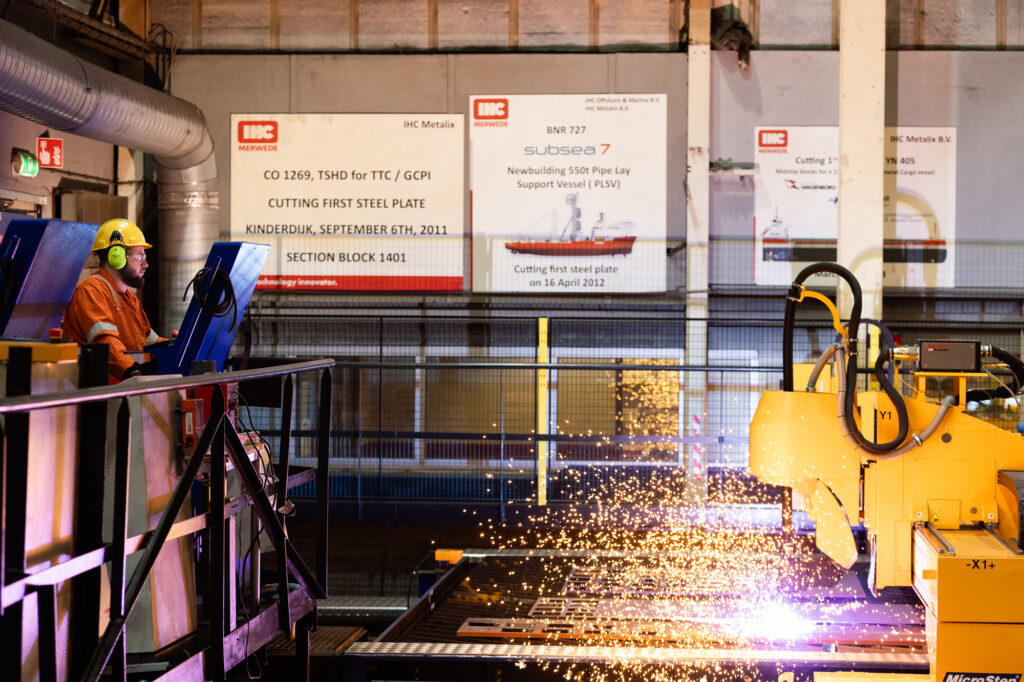

"Efficiently cutting and delivering up to 10,000 tons of steel per ship"

About Metalix | Royal IHC

Metalix is a part of Royal IHC, a Dutch shipbuilder with global operations. They cut and shape plates and profiles for shipbuilding, including commercial vessels, superyachts, and dredgers.

Did you know that one ship can contain up to 10,000 tons of cut and formed steel? Enormous. But a daily routine for Metalix.

Currently, about 50 employees work for Metalix in a two-shift system. General manager Peter Preusting leads the company.

Everything Metalix cuts must also arrive at the end customer at the right time. This, combined with the complexity of the work, demands optimal processes.

“First, we sort the plates. Then they go to the plasma cutting machines, where we not only cut the parts but also apply markings. This makes all parts fully traceable and coded for efficient construction. All cut pieces are placed on a flatbed trailer and delivered to the customer, who can then start working just-in-time with the right parts for their specific construction sequence,” says production manager Martin van Beekveld.

Metalix’s machine park for plate cutting includes:

- two MicroStep plasma cutting machines from 2007 that were recently replaced;

- two MicroStep plasma cutting machines from 2013;

- An additional plasma cutting machine for smaller cutting works;

- An oxy-fuel cutting machine.

Ultimately, they opted for two MicroStep MG 27001.35 Prkl plasma cutting machines. These machines have a working area of 27 meters by 3 meters and are equipped with a cutting head for both straight and bevel plasma cutting, as well as an inkjet marking unit. The Hypertherm XPR300 plasma sources can cut plates up to 40 mm thick, but can be upgraded if necessary.

Both machines have the CNC machine control iMSNC 500 and also feature a wireless control panel with some basic functions programmed in collaboration with MicroStep.

“We were already familiar with the quality of the MicroStep plasma cutting machines and quickly reached an agreement on the delivery of two new machines. We were looking for similar machines that could be efficiently integrated into our production process, but would allow us to work faster and more accurately,” says director of capacity centers Johan de Bie.

The machine and safety equipment were also carefully considered.

“Each machine is equipped with two separate zones, allowing us to cut plates of up to 12 meters by 3 meters at 8 positions,” explains Martin van Beekveld.

Maarten Peelaers, operations manager at Wouters Cutting & Welding, adds: “The machine is equipped with the MicroStep software module ‘workzone management‘, which also divides it into two zones software-wise, additionally equipped with automatic plate alignment. This allows the machine to cut in one zone while the operator sets up a CNC program in the other zone, determining the starting point and alignment. The module is also extended with the standard interface for the crane.”

There are two separate personnel-safe cutting zones per machine, using automatic door locking and light guards.

“All of this ensures that cutting and intermediate movements proceed faster, but operators can still safely access the machine if necessary.”

More cases

Luyckx | Microstep

“Discover how Luyckx boosts its productivity with the new MicroStep CombiCut from Wouters Cutting & Welding. Read their story here.”

Singeling | PEMA

Singeling purchased a Skymaster Pro APSi welding manipulator for automated PTA welding from Wouters Cutting & Welding. Read their story here.

PariMetal | MicroStep

Cutting 3000 tons of steel per year. For this, PariMetal purchased a MicroStep plasma cutting machine from WCW. Read their story here.

Looking for a cutting or laser machine?

Demo in our showroom or no-obligation appointment?

Or call us +32 3 475 98 25