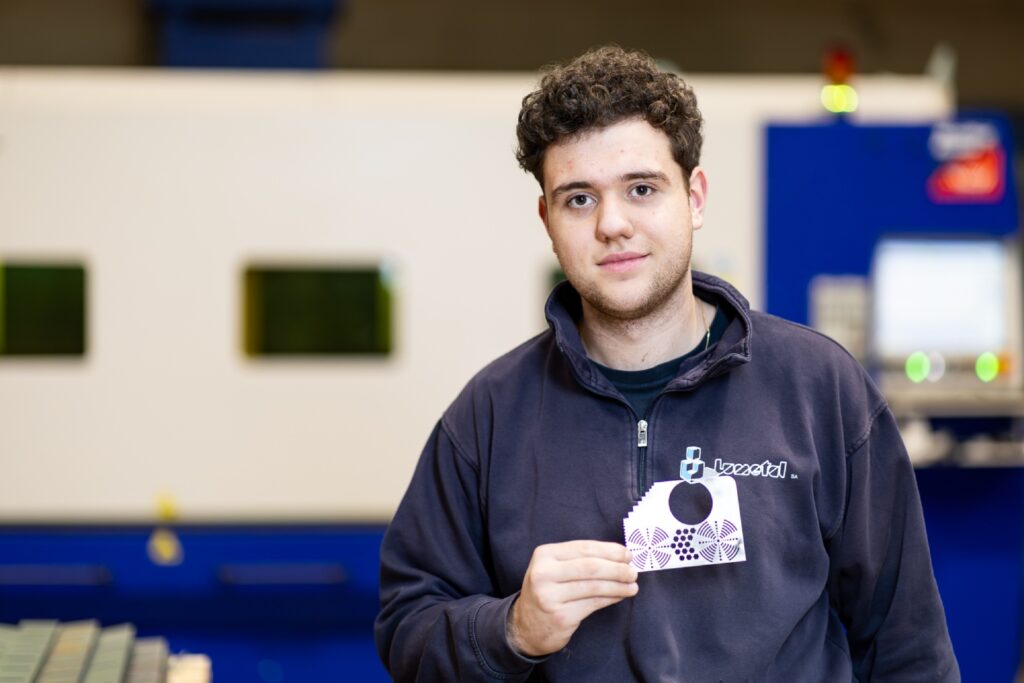

About Lumetal SA

Since 1993, Lumetal has provided the most diverse welding, cutting and construction work for a wide range of customers in Belgium, Germany, the UK and Luxembourg. In 30 years time, their small 180 m² workshop has grown into a large 1,400 m² one. Their modern machinery and quality staff make all the difference to them.

Lumetal used to have a waterjet and a plasma cutting machine, but something was still missing, says founder Luc Janclaes:

“With plasma, we often did not achieve the desired accuracy. This was particularly critical for thinner stainless steel sheet metal. With the waterjet, we did succeed, but the process then took far too long. In fact, we were constantly living with those two extremes and the obligatory choice between either accurate or fast.”

And this in a sector where both accuracy and speed are major assets. Gradually, the idea of switching to laser cutting grew. The waterjet stayed, but the plasma cutter disappeared.

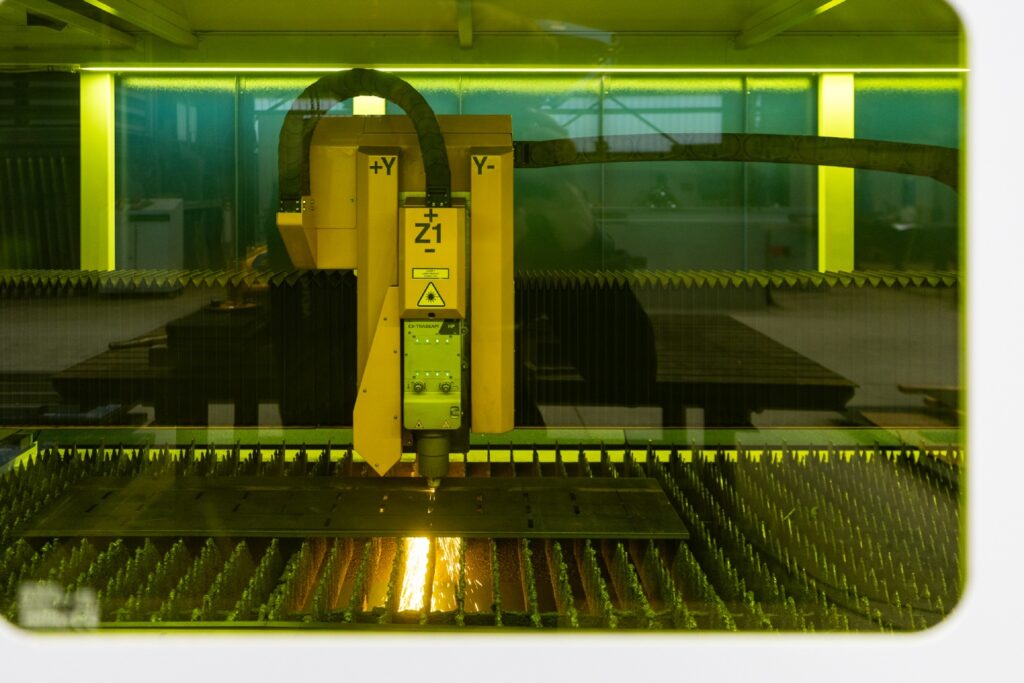

They found their new laser cutting machine at Wouters Cutting & Welding in the high-precision MSF Compact from MicroStep. A machine that cuts smoothly through mild steel up to 20 mm thanks to the 4kW IPG laser source. And that at low operating costs and with easy maintenance.

“It is true that in our region there are enough companies to which we could outsource laser cutting work, but we still opted for our own laser. This is in the interest of the autonomy it gives us: after all, it strengthens our effectiveness, response time and flexibility towards customers. And these are precisely the aspects that have shaped our reputation as a solid partner since Lumetal’s foundation.”

The MSF Compact was the ideal choice for Lumetal. Thanks to the extendable cutting table, the MSF Compact takes up relatively little space. Partly because of this, the machine could be installed and connected quickly. An additional advantage is that the machine requires no warm-up time as is the case with CO2 laser cutting machines. When you switch on the machine, it is ready for use.

Another bonus? Lumetal can choose which software they use for the machine.

“We are not tied to a fixed package, as is the rule with many other suppliers. Moreover, the control programme is compatible with our software systems and drawing programmes.”

Supplying a quality machine is one thing, but the level of service has to be the same. Nic Wouters of Wouters Cutting & Welding explains.

“We are not just another machine shop, quite the contrary. In the customer’s interest, we even hold an efficient response with our own service department very dear. Ultimately, service within our client’s process should never be an operational bottleneck.”

The entire process, from the order to the assembly and commissioning of the laser cutting machine, took barely six months.

“We immediately noticed that WCW has a lot of know-how and experience. This also became clear during the training here on site, which took place in June.”

Thanks to their new machine, Lumetal is able to accommodate further orders without sacrificing speed or quality. And that’s what they signed up for from the start.

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

Looking for a cutting or laser machine?

Demo in our showroom or no-obligation appointment?

Or call us +32 3 475 98 25