About Dulasta Metaalbewerking bv

For more than 25 years, Staphorst-based company Dulasta has been a specialist in large sheet metal work and producing components for the transport sector, crane construction and more.

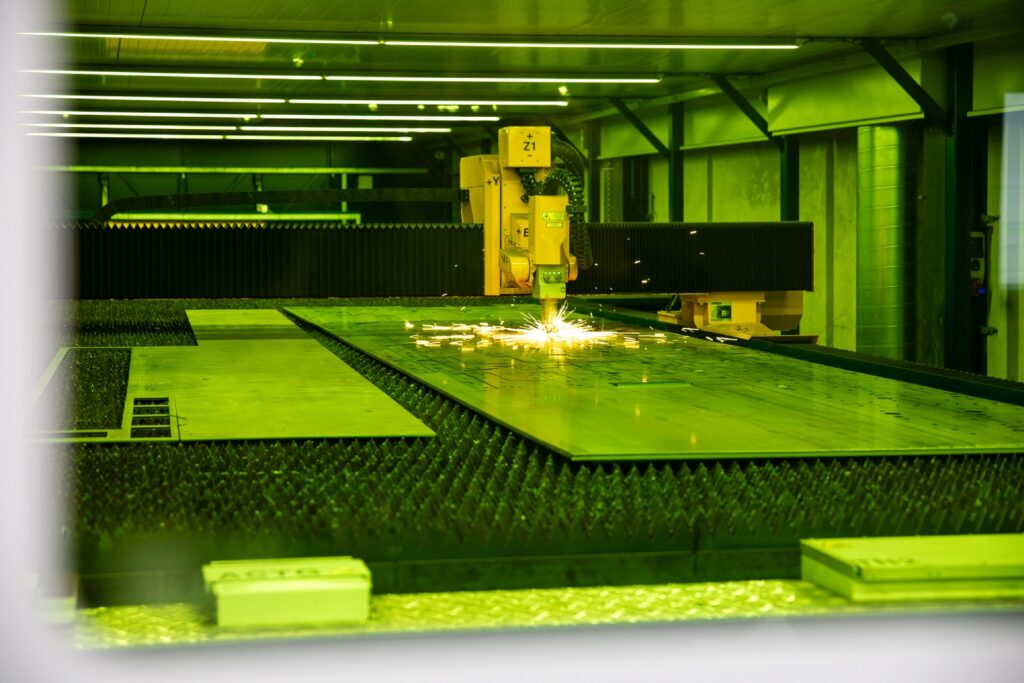

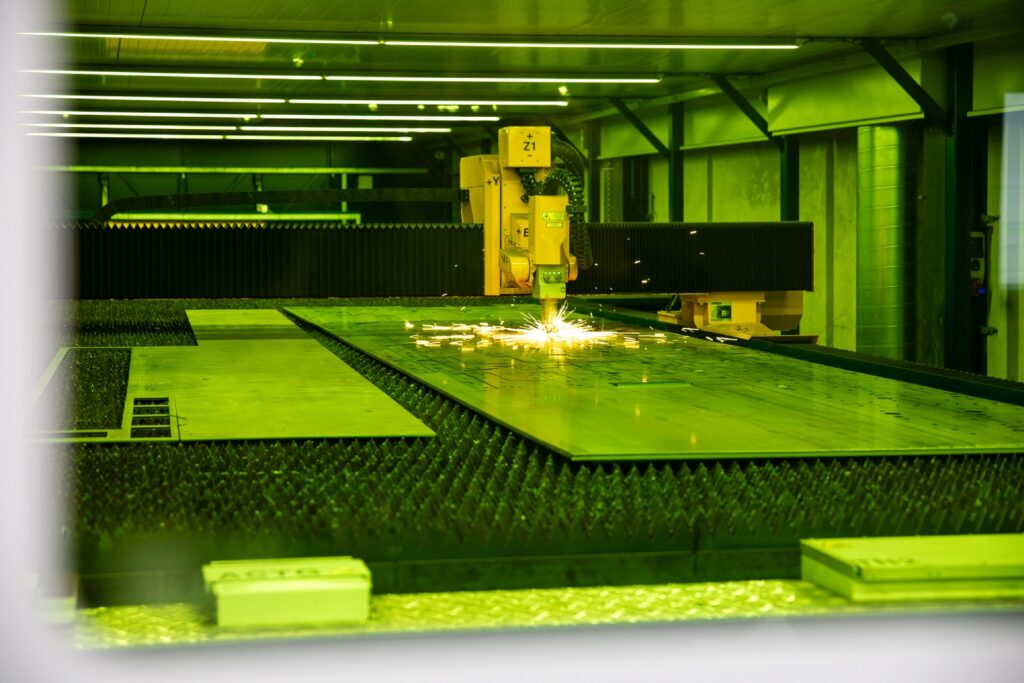

For large sheet metal work, you need big, powerful machines. With their current plasma cutter, a 27-metre MicroStep MG, Dulasta can already do a lot of cutting work, but in some cases, accuracy and finishing are key. Especially if you want to cut high-quality weld edges, for example.

We talked to René Mulder, head of production at Dulasta.

“We quickly knew we were looking for a laser cutting machine. Such a machine could give us the high-quality finish we wanted. Our search eventually led us to about three options. One was MicroStep’s MSF Pro, equipped with a bevel laser cutting head and 15 kW nLIGHT CFX fibre laser.”

With the bevel laser cutting head, weld edge preparations can be cut up to 45°. Combined with the CFX 15 kW source, it is possible to cut bevel in steel up to a plate thickness of 25 mm. For loading and unloading material, the machine is equipped with a MicroStep changeover table that significantly reduces downtime and increases machine productivity.

“It is quite a unique machine considering its large size (16 metres long, 3 metres wide). This means that the machine had not yet been extensively tested or trialled. Given that we already bought other MicroStep machines and have been working with Wouters Cutting & Welding for 15 years, we had full confidence in the machine. After a few extensive demos, we decided to once again choose our trusted supplier, Wouters.”

Today, Dulasta has been working with the MSF Pro for about a year.

“As already mentioned, our machine is quite unique. Depending on the material we cut, we have to adjust the machine differently. That can be a bit of a challenge at times, but with Wouters’ help everything always goes smoothly.

Without the MSF Pro, we would have to outsource this kind of cutting work. Of course, we’d rather not do that, because it increases the costs for the end customer and that way we would have to outsource production. We are therefore glad we chose to invest in our own laser cutting machine.

It’s always a pleasure doing business with Wouters Cutting & Welding. If we need cutting or welding equipment again in the future, we will definitely contact them again.”

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

Looking for a cutting or laser machine?

Demo in our showroom or no-obligation appointment?

Or call us +32 3 475 98 25