Waterjet Cutting

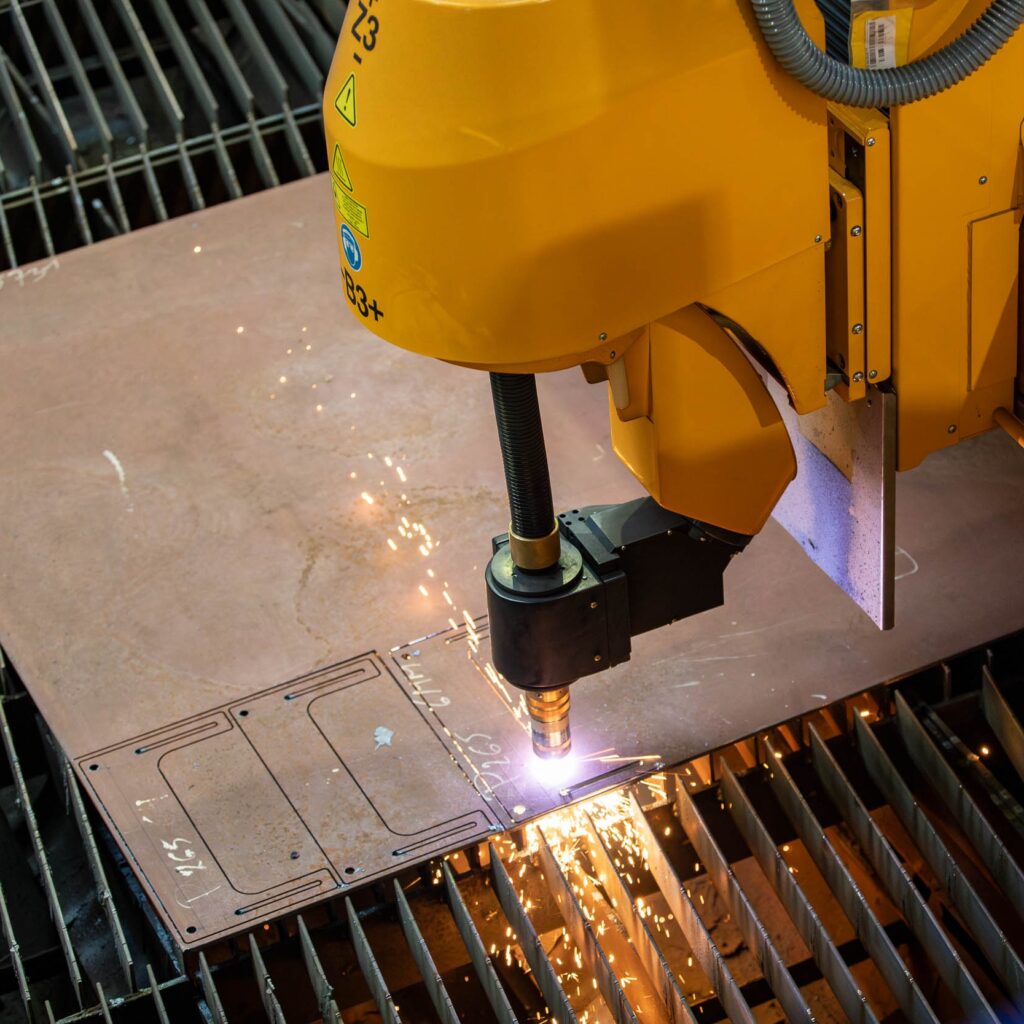

With a waterjet cutter, you cut a variety of materials: from metals to glass and plastic. Waterjet cutting is a very precise cutting technique perfect for cutting heat-sensitive materials.

How does waterjet cutting work?

A waterjet cutter operates with water under high pressure, up to 6000 bar.

In addition, the waterjet cutting machine also adds abrasive sand to the water stream. Fine, sharp particles that give the water the necessary ammunition to cut through your materials.

The abrasive sand, combined with the high-pressure water, ensures the most precise cuts in various types of materials. A high-pressure pump provides sufficient water pressure.

Typically, there are two types of pumps:

- Direct-driven

A direct-driven pump powers your cutting head directly. This pump is usually more budget-friendly and can be found on our Swift-Cut machines. - Intensifier

This pump uses an additional hydraulic motor to power the cutting head. This makes the pump a bit pricier than the direct-driven pump. You’ll find an intensifier pump more often on heavier machines, like MicroStep’s.

What should you consider with waterjet cutting machines?

- Versatile

While other cutting techniques are only suitable for various types of metal, a waterjet cutting machine can cut through almost any type of material. From plastics and rubber to glass and ceramics; the possibilities are enormous. - High precision

Waterjet cutting is the most precise technique in our range. Is a very high finish grade your main requirement? Then you should opt for a waterjet cutting machine. - Perfect for heat-sensitive materials

Oxy-fuel, laser, and plasma cutting methods use heat to cut through materials. Heat can alter the composition of some materials, and other materials such as plastics simply do not tolerate heat.. For these applications, a waterjet cutter is ideal. - Accuracy takes time

Waterjet cutting is an extremely precise technique, but requires more time. Therefore, it’s important to consider what is more important: cutting speed or cutting accuracy. - More maintenance required

Waterjet cutting machines require more maintenance and inspection than our other machines. Water causes faster wear, and the high-pressure pump also needs regular checks.

Our references in waterjet cutting

Spimabo | Swift-Cut

Read more →

Which waterjet cutting machines do we offer?

MicroStep

MicroStep is a high-end brand that offers a wide range of possibilities. From smaller installations to complete production lines with the latest technologies. With more than 250 completed projects, we will find the perfect machine for you as well.

Swift-Cut

Swift-Cut machines are compact and budget-friendly. Moreover, they are easy to use. These machines are typically found in smaller companies with lower cutting needs. Wouters Cutting & Welding is the exclusive distributor of Swift-Cut in the Benelux.