CASE

Geldof

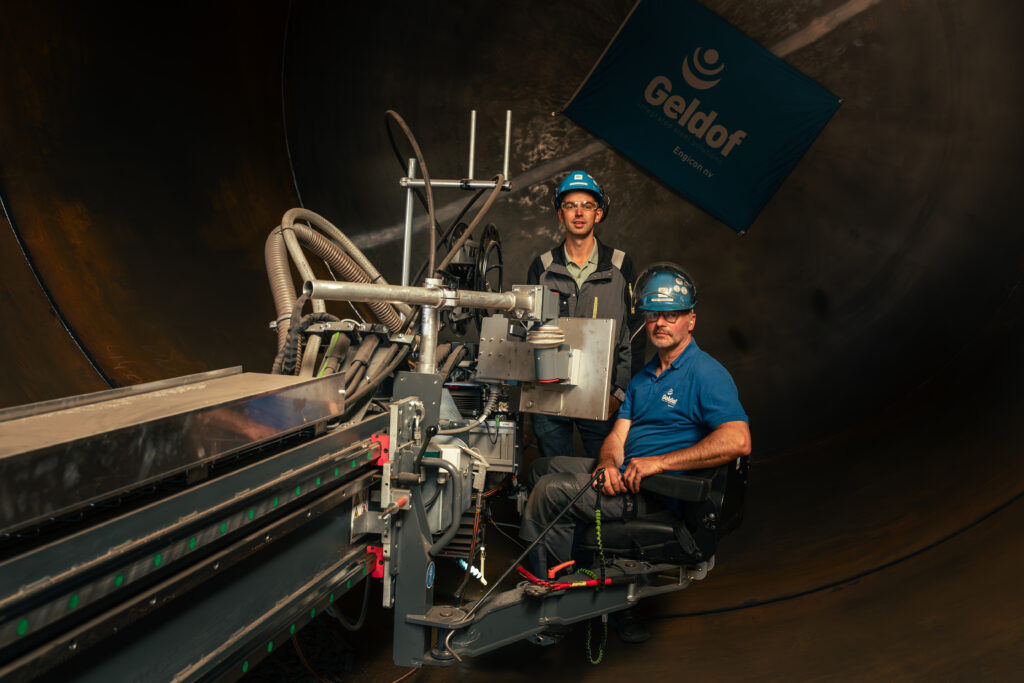

“Thanks to Wouters Cutting & Welding, we have access to the right technology and service.”

Discover this case

About Geldof

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Maximum efficiency gains with PEMA welding columns for large pressure vessels

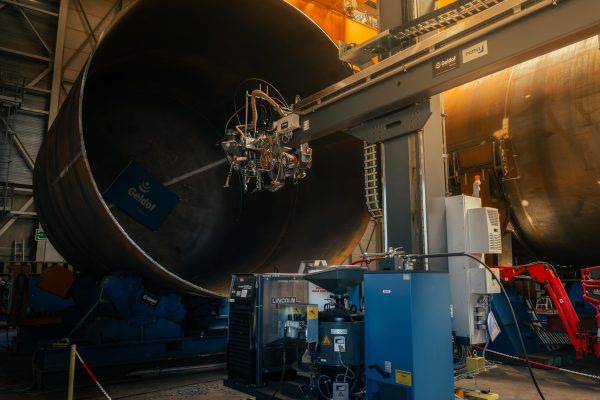

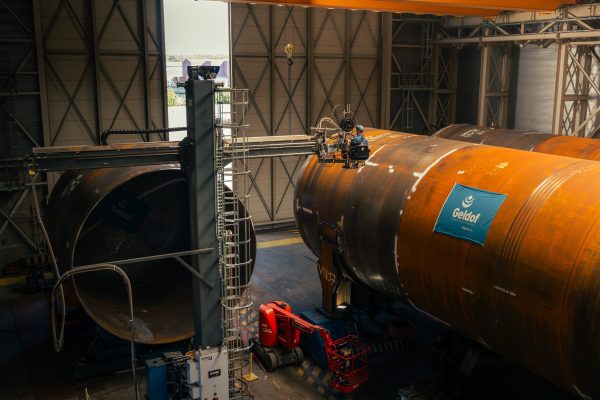

To strengthen its pressure vessel production, Geldof invested in two identical PEMA welding cranes, supplied and supported by Wouters Cutting & Welding. The new installations use the LSO (Long Stick Out) welding process, which enables the company to achieve up to 40% efficiency gains when welding thick plates. The combination of advanced technology and reliable service makes the project a success story in every respect.

For an international carbon capture & storage project, the company had to produce eight pressure vessels with a diameter of 7.2 m and a wall thickness of 34 mm within one year. This was a task that required maximum efficiency.

LSO welding process boosts speed and production capacity

“Our existing SAW installations did not offer the speed we needed,” says Dieter Vandeputte, maintenance & facility manager at Geldof. “Through Lincoln, we came across the LSO welding process. This increases the deposition rate, reduces the number of layers, and saves a considerable amount of time.”

For the project, Geldof opted for two PEMA welding cranes, designed according to their specific production requirements and supplied by Wouters Cutting & Welding. Each crane has a reach of 8 m high and 6 m wide, can rotate 360° and is fully mobile thanks to its installation on roller bridges instead of fixed rails.

Mobile, stable and safe setup for consistent welding results

“This keeps our floor free and allows us to bring the crane to the workpiece,” explains Vandeputte. “With counterweights of 1.32 tons each, the cranes are perfectly balanced. The linear guides ensure a stable, vibration-free arm, which is essential for consistent welding results.”

The installations are equipped with Weld Control 100 control, automatic weld seam tracking, and flux recovery with filtering, which not only increases efficiency but also safety and sustainability. Thanks to 1,000 kg welding wire drums, welders can work continuously for long periods of time.

Strong technical support and fast implementation for future-proof production

According to Geldof, the collaboration with Wouters Cutting & Welding was exemplary. “Service was a decisive factor for us,” emphasizes Vandeputte. “WCW has the right technical knowledge, spare parts, and remote support. Their installation team worked quickly and professionally. Both cranes were operational within three weeks.”

Today, the installations run daily in two shifts of certified LSO welders. “We can now handle larger structures in less time and with higher quality. Thanks to WCW’s technical support, we are ready for the future.”

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

DEOM | MicroStep

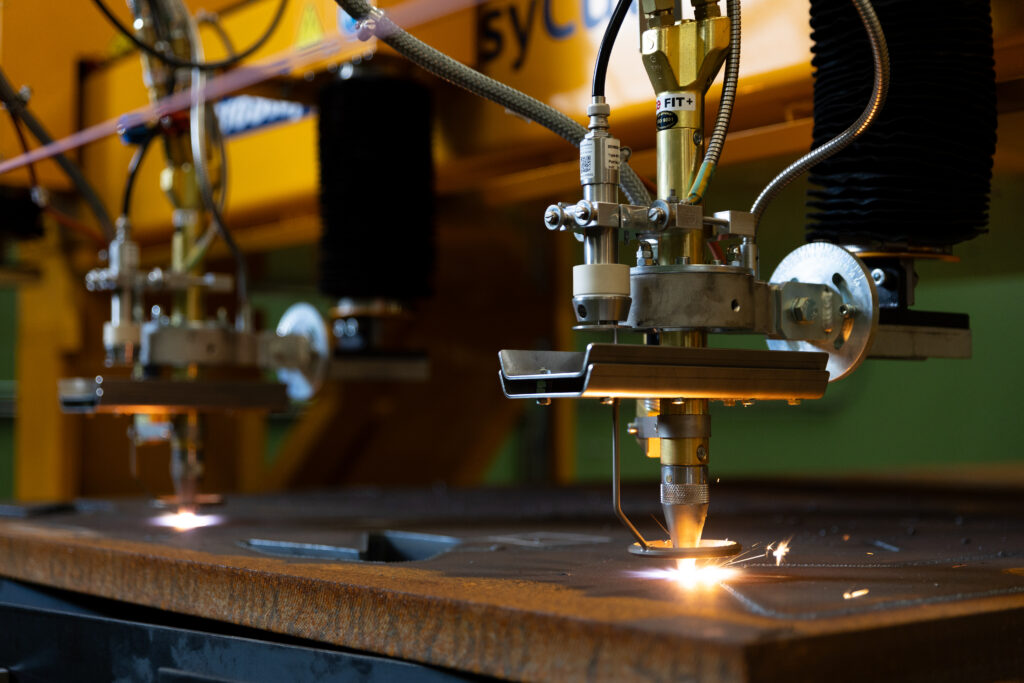

Deom’s new MicroStep MasterCut combines high cutting accuracy with speed and automation.

Looking for a cutting or laser machine?

Demo in showroom or no-obligation appointment?

Or call us on +32 3 475 98 25