About Snijtech

Snijtech, based in Joure, was originally started as a supplier of cutting services only, but today also has a sheet metal department, a 2D bending department, a 3D forming department and a profile machining department. Snijtech can handle both custom work and larger projects, even in the form of actual construction kits. Quality has been central to this for 30 years.

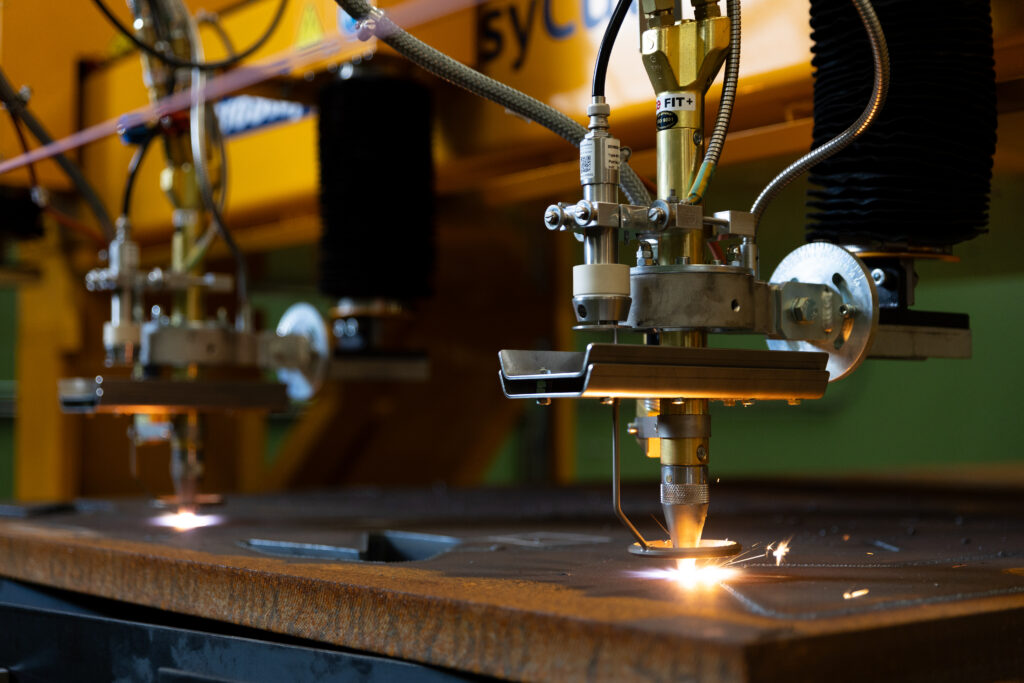

Farewell to plasma

Until recently, Snijtech still had three plasma cutting machines in use. However, this cutting technique was discontinued for various reasons.

Instead, Snijtech opted for a laser cutting machine. Not only does it work faster, it is also more efficient, especially with thinner materials. Managing Director Jacco Klok: ‘The vast majority of our cutting work involves thinner sheet material. In addition, we have a water jet cutting machine for thicker material. So we no longer had any need for plasma cutting machines.’

A fine piece of technology

Many manufacturers offer laser technology, but in the end, Wouters Cutting & Welding won the case. The 15 kW MSF PRO from Microstep is a fine piece of technology. The machine has a working area of 12,000 mm x 3,000 mm and is also equipped with an inkjet station for marking and an automatic hydraulic exchange table, which is useful for sorting.

However, what is unique about Microstep is the bevel control, which enables weld edge preparation with laser cutting quality up to 45°. Nic Wouters, managing director at Wouters Cutting & Welding, explains: ‘The bevel head corrects deviations in the X, Y and Z axes. At the front of the machine is the calibration station, which eliminates any mechanical deviations.’

Thanks to the new machine, Snijtech has the technological edge that so many companies are looking for.

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

Looking for a cutting or laser machine?

Demo in our showroom or no-obligation appointment?

Or call us +32 3 475 98 25