CASE

MALLENS CONSTRUCTIETECHNIEK

“We weren't just looking for a machine, but a partner who could guarantee service.”

Read this case

About Mallens Constructietechniek

Mallens Constructietechniek in Helvoirt has been processing steel for a wide range of applications for more than forty years. What started as a one-man business in 1979 has grown into a specialised construction company that today is active in steel constructions for industrial buildings, sports halls, residential construction and agricultural buildings, among other things. They also produce stairs, platforms and fencing. Since 2020, son Robin Mallens has been at the helm.

For a long time, this punching and shearing machine was central to the sheet metal work, but it increasingly became a bottleneck.

‘In 2023, we reached a tipping point,’ explains Mallens. ‘The products became more complex and we had to outsource cutting work more and more often. This had a direct impact on our delivery times and our own productivity. Our punching and shearing machine was simply idle too often.’

‘We received several suppliers and took a look at different companies,’ says Mallens. ‘But we often dropped out: too little service, uncertainty about continuity or machines from the Far East without proper support. Manuals in Chinese, unclear software… That didn’t give us confidence.’

The deciding factor came via references from their own network. Both a cutting partner and another supplier of Mallens were already working with Wouters Cutting & Welding.

‘That gave us confidence. We needed a supplier who could not only deliver a machine, but also guarantee long-term service and support.’

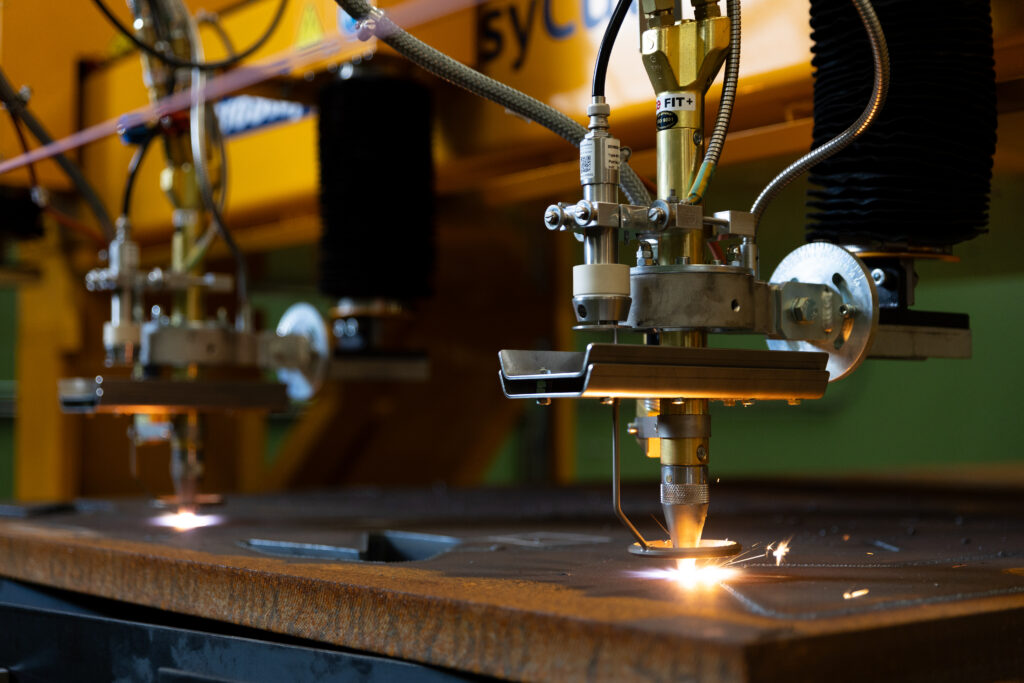

‘In fact, we had the choice between plasma, water jet and laser,’ says Mallens. ‘Given our materials, dimensions and the fact that we provide clear coding for many of our cuts, WCW recommended the Photon Lite laser cutting machine from Esprit Automation.’

The compact laser cutting machine, equipped with a 6 kW fibre laser source, was installed in the production hall at the beginning of January.

‘We have only been working with it for a short time, but the results are already exceeding expectations,’ says Mallens. ‘We use the machine every day. The speed and accuracy are impressive. Parts are cut in a single operation, including holes and recesses that we used to punch, and completely burr-free. Post-processing is often no longer necessary.’

The 1,500 x 3,000 mm cutting table is ideal for processing steel plates between 3 and 20 mm thick. Mallens also immediately invested in a vacuum lifting device to load plates safely and efficiently.

‘Nesting is done in the office, but there is direct contact with the workshop via an app,’ explains Mallens. ‘Operators can also easily recall previous programmes with LiveControl, even to utilise residual material. That makes us extremely flexible.’

For Mallens, the choice of WCW was not just a technological decision.

‘I am very satisfied with the compact, fast and accurate machine,’ concludes Mallens. ‘But just as important is the service. Wouters did what they promised. They didn’t just deliver a machine to us. We were able to get started with it independently in no time.’

More cases

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

DEOM | MicroStep

Deom’s new MicroStep MasterCut combines high cutting accuracy with speed and automation.

Looking for a cutting or laser machine?

Demo in showroom or no-obligation appointment?

Or call us at +32 3 475 98 25