About Metaalwerken Wim Baekelandt

Since 1999, Metaalwerken Wim Baekelandt has been building a strong reputation in steel structures and metalworking. With a team of eleven welders, the company mainly works for regular customers such as Myldes, Denbouw and Gebo Construct. Their metal structures are used in a wide range of projects, from industrial buildings to retail structures and amusement parks.

A reliable cutting machine is essential

‘We supply all components fully customised so that our customers can assemble them immediately on site,’ says manager Anthon Baekelandt. ‘A reliable cutting machine is essential for this. That’s why we chose MicroStep again.’

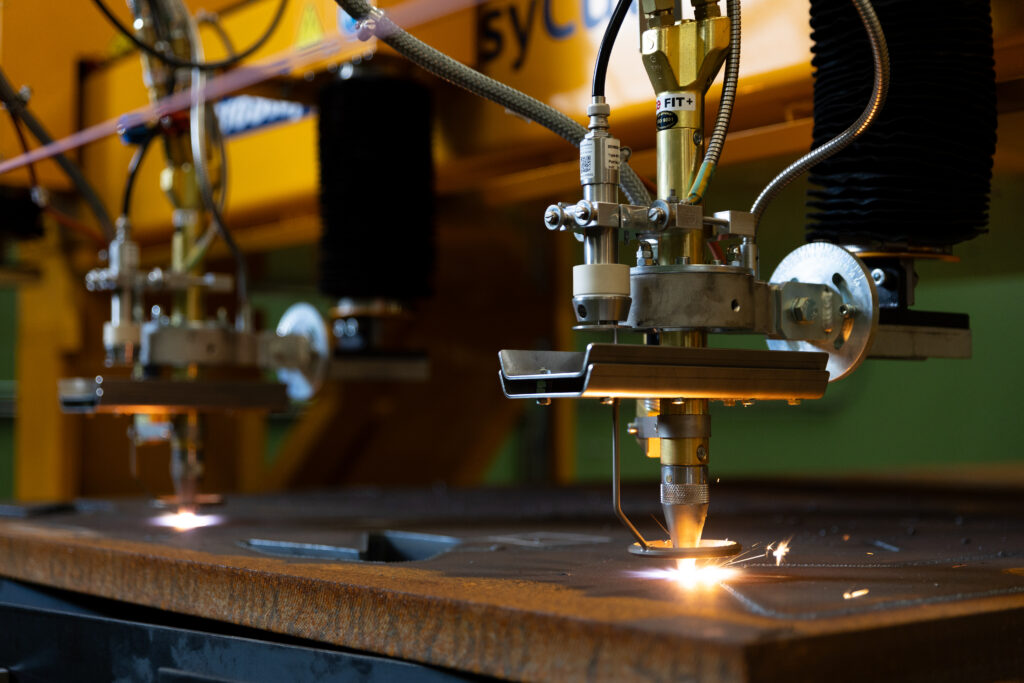

MicroStep MasterCut

To accommodate the growing production capacity, Baekelandt invested in a MicroStep MasterCut: a versatile CNC cutting machine that excels in plasma cutting and oxyfuel cutting. The machine can also be expanded for cutting and marking pipes, profiles and bends, offering maximum flexibility for a wide range of applications.

‘With the new MasterCut, we cut 95% of all our plates, from 1 to 40 millimetres,’ says Baekelandt. ‘Our previous MasterCut ran smoothly every day for fourteen years. That confidence in the technology was the deciding factor in choosing MicroStep again.’

Higher accuracy, shorter cycle time

The new CNC cutting table is equipped with automatic height measurement of the cutting head, which significantly speeds up the process. ‘We used to have to set the height manually, but now it’s done automatically,’ explains Baekelandt. ‘This ensures greater accuracy and a shorter cycle time.’

In addition, the machine has vibrating chutes for automatic waste disposal. ‘That saves a lot of time,’ he says. ‘Before the new machine arrived, each bin was emptied separately with a crane. Now the vibrating chutes direct the waste to a single container. One employee can empty it every two weeks, without dismantling or downtime.’

Everything perfectly prepared

The installation and start-up were supervised by Wouters Cutting & Welding. ‘Their technicians prepared everything perfectly,’ says Baekelandt. ‘The transition went very smoothly because the operation is intuitive and the software is clear. We were able to get started almost immediately.’

‘Wouters Cutting & Welding stands for service, knowledge and thinking along with the customer,’ he concludes. ‘Thanks to the new MicroStep MasterCut, we work faster, more accurately and with less maintenance. That makes a world of difference in our daily production.’

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

DEOM | MicroStep

Deom’s new MicroStep MasterCut combines high cutting accuracy with speed and automation.

Looking for a cutting or laser machine?

Demo in showroom or no-obligation appointment?

Or call us on +32 3 475 98 25