More efficient, more flexible and more competitive

The old machine no longer met the high standards that HYE sets for its products. After cutting, too much post-processing was required to achieve a beautifully finished product: deburring, chamfering, drilling and slotting holes… Too much time was lost.

‘By investing in a new machine ourselves, we want to become more efficient, flexible and competitive. We should have done this three years ago,’ laughs Sebastián Bossuyt, steel construction manager.

Significant catch-up

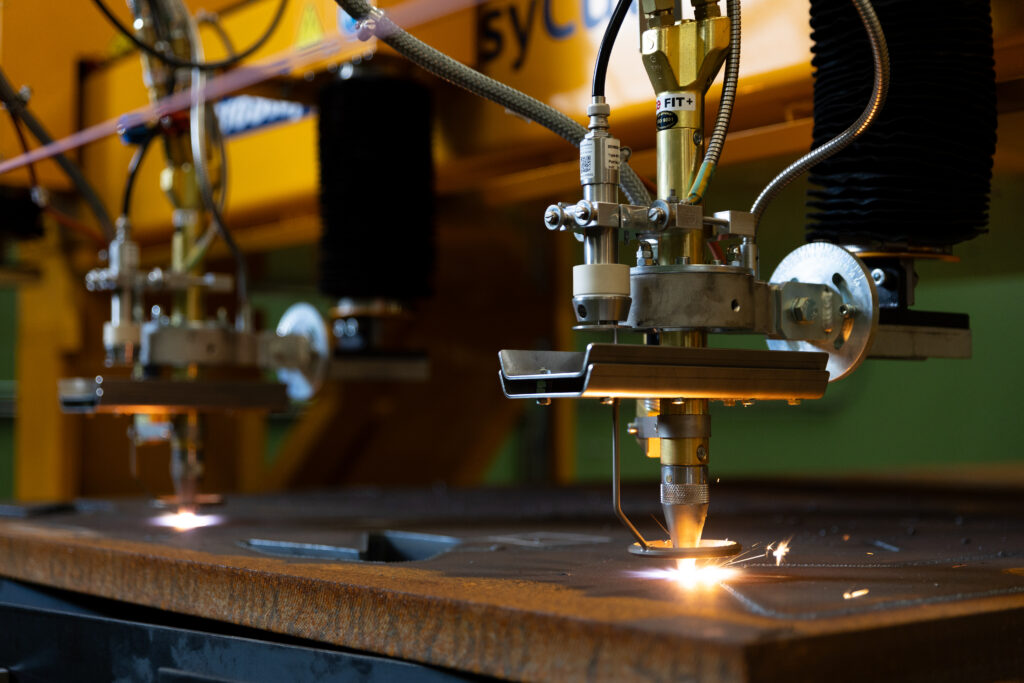

The final choice was a MicroStep plasma cutting machine with a 12 x 2.5 metre table and a Hypertherm XPR300 plasma cutting source with automatic gas console. The machine was equipped with an oxy-fuel torch carriage, a continuously rotating plasma rotator for bevel cutting and a drilling unit with a tool changer.

‘Every technology we have added contributes to the finish of the pieces. Not only do we save time because we no longer have to do manual work, but the quality of our work has also improved. With this powerhouse, we are making a significant catch-up and have everything we need to take on larger projects,’ says Bossuyt.

Practising together

‘Wouters Cutting & Welding is a partner that really thinks along with you and helps you organise your production more efficiently. What’s more, they always honour their agreements. And the service? We already know from the previous machine that it’s excellent.’

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

Looking for a cutting or laser machine?

Interested in a demo in our showroom or a no-obligation appointment?

Or call us on +32 3 475 98 25