CASE

CEVO System

CEVO System Boosts Production with New Cutting Machine

Discover this case

AboutCevo System

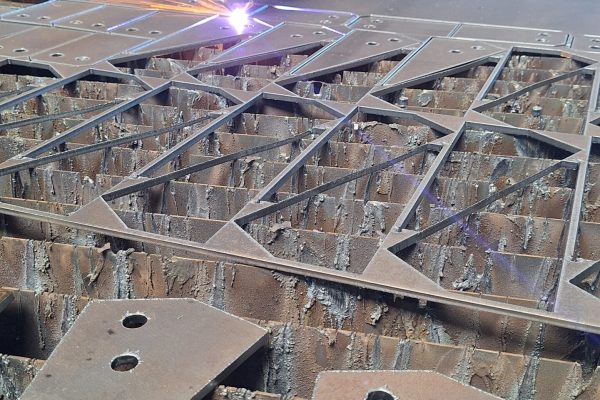

CEVO System, based in Tessenderlo, specializes in steel frame construction. The company designs, manufactures, and installs custom metal structures—ranging from simple industrial halls to complex applications like machine supports, walkways, and skids. By keeping all production in-house, CEVO System maintains high quality standards and short delivery times.

The Hypertherm XPR170 plasma source provides a noticeable acceleration of the cutting process. “We can now cut relatively thick plates faster, with fewer burrs and cleaner holes. Post-processing is hardly needed anymore.” CEVO System can now plasma cut up to 30 mm thick—an improvement over the previous 20 mm limit.

The transition to the new machine went smoothly. “Our operator was already familiar with the system. The new software is even more intuitive and much more automated,” says van Briel. “For example: NC files can now be loaded in bulk and automatically sorted. That saves us a huge amount of prep time.” The control panel remains largely the same, minimizing the need for additional training.

Just like 18 years ago, CEVO trusted Wouters Cutting & Welding for this investment. “Their service is excellent. Many issues can be solved remotely, and if not, a service engineer is quickly on-site. That fast response time made all the difference.”

More cases

Mallens | Esprit

How Mallens Constructietechniek achieves greater speed and precision with the Esprit laser cutting machine. Discover the role of technology and service at WCW.

Geldof | PEMA

Engicon NV – Geldof is a Belgian metal construction company specializing in tanks, pressure vessels, dry bulk handling, and tank maintenance for the petrochemical and process industries. From its headquarters in Harelbeke, Geldof carries out EPC projects from design to assembly for customers worldwide. With more than 170 employees and modern machinery, the company guarantees high-quality steel structures for demanding industrial applications.

Baekelandt | MicroStep

Baekelandt Wim Metaalconstructie is a family business based in Kuurne, specialising in metalworking and custom steel structures. Since 1999, the company has been providing high-quality solutions for industrial and agricultural applications, including sheds, halls, staircases, platforms and structural steel components.

Looking for a cutting or laser machine?

Demo in showroom or no-obligation appointment?

Or call us at +32 3 475 98 25