Plasma cutting

Our best-selling cutting technology. Plasma cutting machines are versatile and require relatively little maintenance.

How does plasma cutting work?

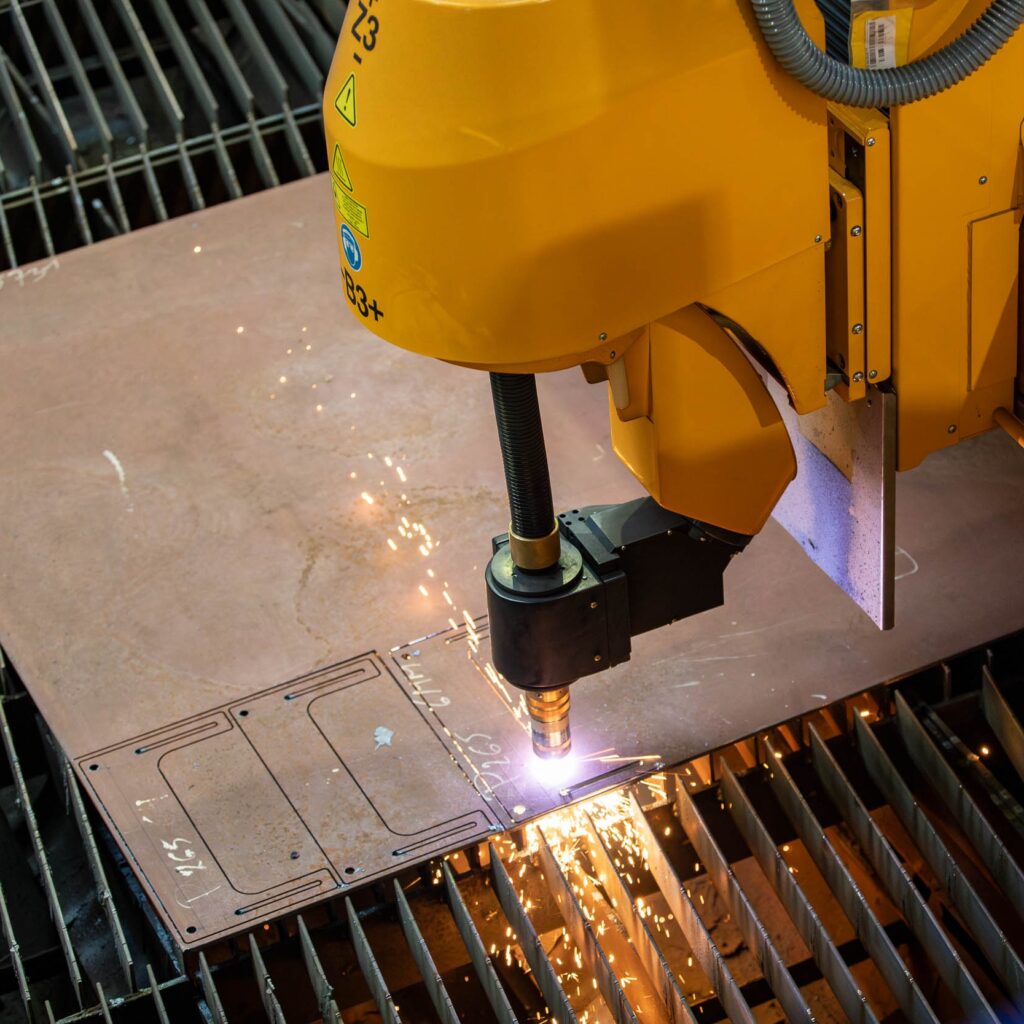

In short, plasma is created when a gas is heated. In this case, the gas is expelled through a nozzle by your cutting machine. Once it comes into contact with electricity, the machine creates plasma. Consequently, plasma cutting only works on electrically conductive materials.

The generated heat melts the metal. The gas leaving the nozzle then blows away the molten particles.

What should you consider with plasma cutting machines?

- Plasma cutting machines are user-friendly

All cutting parameters are by default in your machine’s control system. This is different from oxy-fuel cutting machines, where you often configure everything manually. - Suitable up to 50mm

Depending on the plasma source and the material to be cut, plasma cuts sheets up to 50mm thick. Thicker material requires oxy-fuel or waterjet cutting. - Easy to combine

Plasma is easily combined with other techniques, such as drilling, tube cutting, inkjet marking, etc. - Low maintenance

Plasma cutting causes little wear and tear. An annual maintenance is usually sufficient. - Excellent price-to-quality ratio

A plasma cutting machine is often the most suitable solution. With plasma, you deliver solid cutting work in the most frequent sheet thicknesses. Additionally, the cost of a plasma cutting machine is lower compared to a laser or waterjet cutting machine.

Our references in plasma cutting

Real Corp | MicroStep

Read more →

Ivens | Microstep

Read more →

VDW bvba | Swift-Cut

Read more →

Which plasma cutting machines do we offer?

MicroStep

MicroStep is a high-end brand that offers a wide range of possibilities. From smaller installations to complete production lines with the latest technologies. With more than 250 completed projects, we will find the perfect machine for you as well.

Swift-Cut

Swift-Cut machines are compact and budget-friendly. Moreover, they are easy to use. These machines are typically found in smaller companies with lower cutting needs. Wouters Cutting & Welding is the exclusive distributor of Swift-Cut in the Benelux.